SiloCapCal - Silo Capacity Calculator app for iPhone and iPad

Developer: Darren Frost

First release : 08 Mar 2015

App size: 8.99 Mb

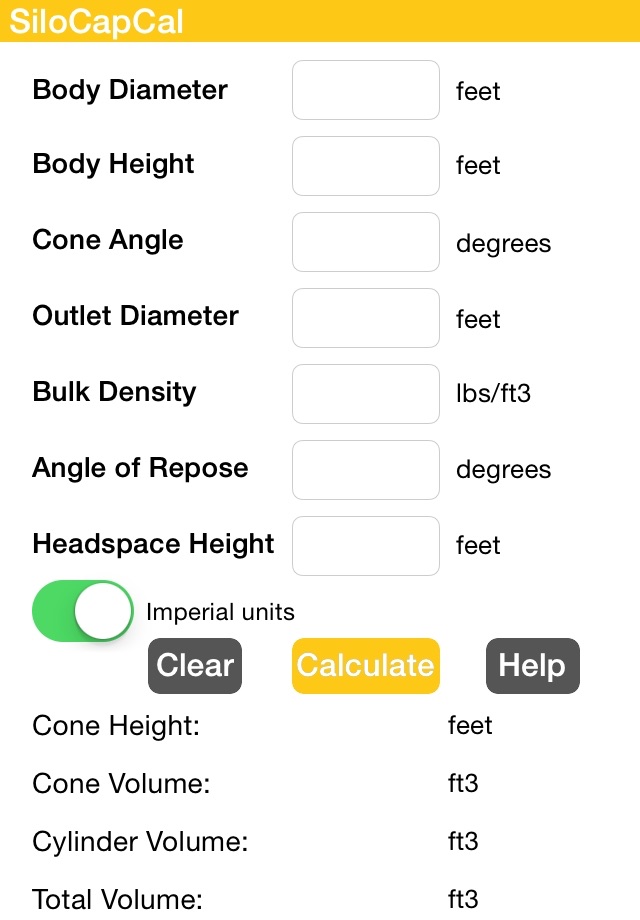

A fast and efficient tool for calculating the volume and actual holding capacity of a cylindrical silo either of a flat bottom design or having a truncated conical discharge hopper with circular outlet.

This tool was developed by a process plant consulting engineer and is intended to help a wide audience including bulk materials handling engineers, project engineers, factory operators, students and of course silo, tank and hopper manufacturers. It can also be used by anyone that wishes to find out the volume of a cylinder with and without hopper and for anyone that wants to know the holding capacity of water then just enter 1,000 kg/m3 against bulk density.

For volume calculations the app requires the silo diameter, height, outlet diameter (if flat bottomed silo) and cone angle with outlet diameter (for conical outlet silo). All non-dependent fields can be left empty or set with 0 values.

Storage capacity capability can also be calculated by entering the bulk handling properties of the material which will fill the silo and used for storage calculations. The user is required to input known data such as bulk density and the angle of repose for the particular material.

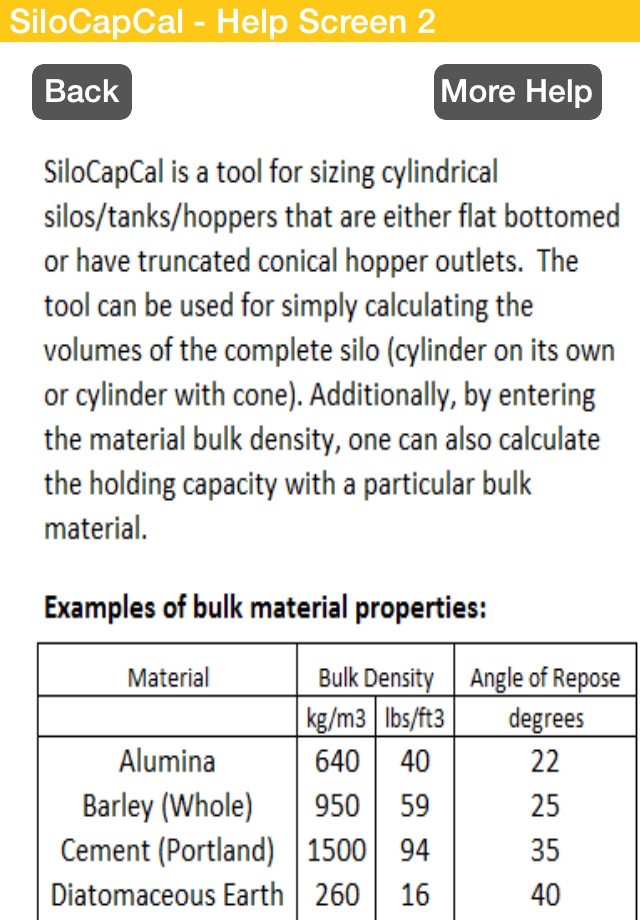

Bulk material properties are widely available, but for quick reference some commonly used materials are listed in the help section.

It should be noted that the angle of repose of a material is based on the material filling the silo from the top via a central inlet, in most cases for powders this can be set at 45 degrees and for free flowing granular materials 25 degrees should be suitable in most cases. If you are not sure of the angle of repose for the material then set it high, as this will make sure the silo holds what is required.

A useful feature for project engineers and silo designers is the ability to set top headspace height (empty void of cylinder above material peak) so that a section of the silo can be left out of the working capacity calculation for times when explosion protection devices and sensors might need fitting in the top of the cylinder, or purely to ensure the silo will hold the desired storage capacity even if the bulk density of the material varies slightly. The material bulk density very often varies depending on product grade, moisture content and other environmental conditions.

It should be noted that if using this tool to calculate dead loads for civil engineering purpose then the weight of the silo itself must be added to the storage capacity plus the bulk density of the material is normally increased by 25% for settled materials so having a higher packed density.